Believe it or not, there are many enterprises still think it is very complicated to do outsource for their plastic injection mold or injection molding project from overseas. All we need to do is, find the RELIABLE supplier. With the right people efficient team, you will figure out that things are much easier than thought. Lyter Engineering Ltd. is expert on plastic injection mold making, we have b...

After the mold manufacturing done, it is the most exciting moment to test the mold and get the first articles. For Injection mold review and first sample confirmation, Lyter Engineering Team will check below items. 1. Exterior: Is the surface texture correct? Are there impurities in the material? Are there any bumps or scratches on the surface of the product? 2. Parting Line: Is there a front...

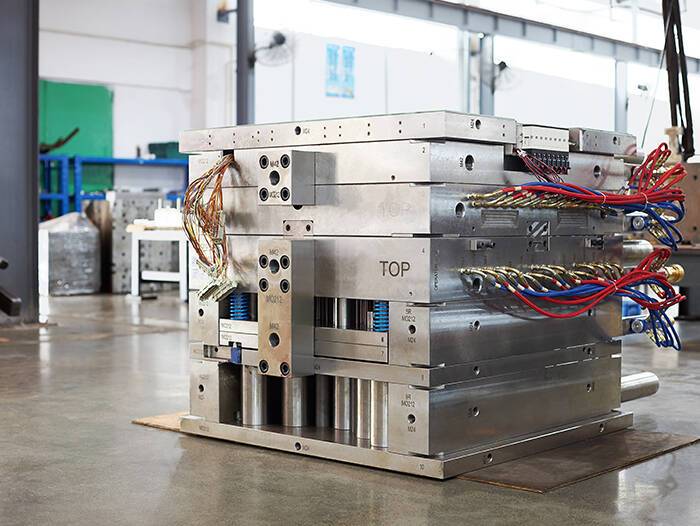

There are many types of plastic molds. Even if the same type of molds, due to the different types of plastics, the beginning and accuracy requirements are different, and the assembly methods are different. Therefore, before assembling, we should carefully study and analyze the assembly drawing and parts drawing, understand the role, characteristics and technical requirements of each part...

Sea and air freight options offered where the tool has been made for overseas customers. Completed molds are splayed and stored in certain area with good ventilation to avoid rusting before delivery. Use wooden crates or metal containers to pack the mold. Put molding parameters sheet and a video disc (including 2D/3D mold drawings, molding parameters, certifications of steel and heat treatment, ho...

We are very glad to announce that we equipped the Japan Sodick wire cutting machine AG400L in house. On the basis of its manufacturing philosophy, Sodick supports various manufacturing processes, including: CAD/CAM product design for mold processing, electrical discharge machining of mold parts, high-speed milling centers, electron beam finishing (especially electronic Bundle PIKA surfa...

Dear Valued Customers, Lyter Engineering Limited will shut down from April 30th to May 4th for the local Labor Day Holiday. We will be back to work on May 5th next Thursday. During the holidays, we can still take care of the quotations, but the respond speed will be slower than usual days. We hope for your kindly understanding. If there are any urgent issues, please feel free to ...

From the below picture, it is the product of the intelligent sweeping robot surface shell. The maximum size of this product is 384.90 mm x ø316.00mm x 130.80 mm, the average thickness is 2.00 mm, the material is PP, the shrinkage rate is 1.018, and it is 512.64 gram. The technical requirements for the plastic parts are that there must be no defects, such as flash, short shot, flow lines, gas mark,...

Die casting aluminum offers several advantages over other metal-forming processes that might make it the appropriate choice to create your aluminum parts. Aluminum alloys are lightweight and possess high dimensional stability for thin walls and complex part geometries. Aluminum withstands good corrosion resistance and mechanical properties as well as high thermal and electrical conductivity, makin...

1. Material choosing Materials are often specified in the early design process and should be mutually agreed by both parties. The designer may discover certain high-performance resins may not be ideally suited for a molder due to viscosity, high glass content or crystallinity. A resin may be chosen for specific physical or chemical-resistance properties but may be very difficult to mold or maintai...

© Copyright: 2026 Lyter Engineering Ltd. All Rights Reserved

IPv6 network supported