Injection-molded Part Design Points

Shutoff in Plastic Injection Mould

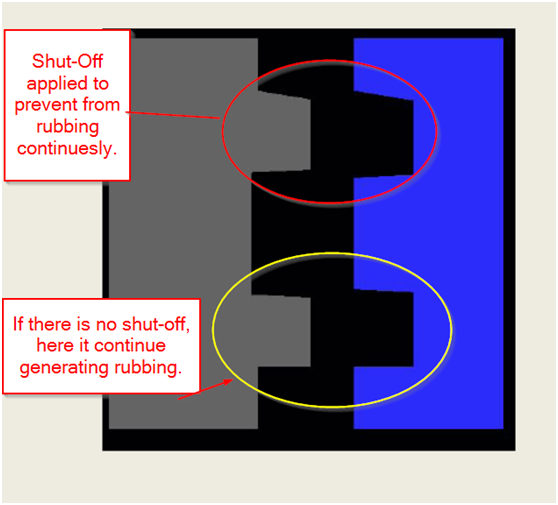

Shut-Off angle is applied for prevent the mold parts (Core and Cavity) from crashing into one another if there is any slight misalignment upon mold parts closing.

Shut-OFF angle also prevent galling that would occur if vertical metal faces were rubbing against each other.

Eg.

Note:

A draft angle exists for purposes of part

release, while a shutoff exists to prevent mold parts.

Shut-OFF angle also come there where

Parting Line and Tooling direction of mold comes parallel.

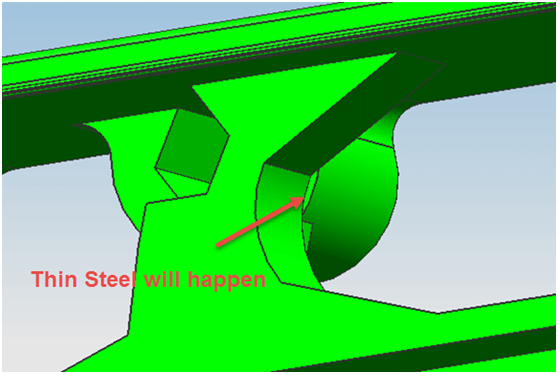

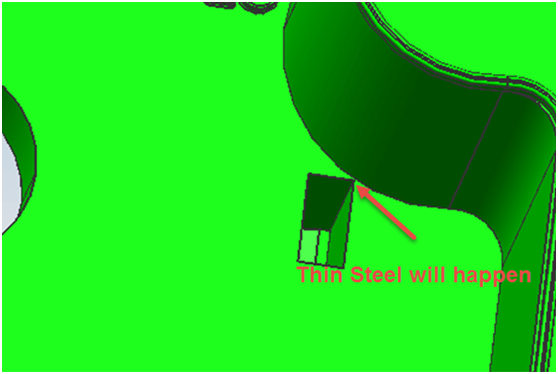

Thin

Steel in Plastic Injection Mould

Thin Steel or Sharp Steel refers to areas of mold steel to be with

thinner areas.

Why thin steel happens?

Incorrect part design. Small gap between

walls of a plastic part.

Below are 2 examples:

Disadvantages of thin steels

When creating a plastic part or tool, thin

steels should be avoided as much as possible. The disadvantages are:

Shorten the plastic injection mould life

Get mold technicians or machine operators

hurt

Categories

latest blog

© Copyright: 2026 Lyter Engineering Ltd. All Rights Reserved

IPv6 network supported