The Hard Rail or the Linear Rail? Which One Is Better in CNC Machining?

We often hear that CNC machining centers are divided into hard rails and linear rails. Customers will ask when purchasing a machining center: Is the hard rail better or the linear rail better? What is the difference between the two?

01 What is a hard track? What is a linear track?

The hard rail refers to a casting in which the guide rail and the bed are integrated, and then the guide rail is processed on the basis of the casting. That is, the shape of the guide rail is cast on the bed, and then processed by quenching and grinding. There are also the bed and the guide rail are not necessarily integrated. For example, the steel-inlaid guide rail is nailed to the bed after processing.

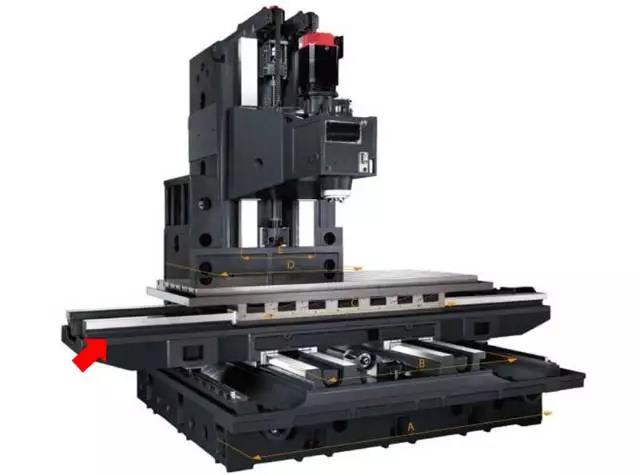

Machine Using Linear Rails

02 The Hard Rail or the Linear Rail? Which One Is Better in CNC Machining?

In fact, there is nothing good or bad about hard rails and linear rails, they can only be said to be suitable or not, because their focus is different. Let's take a look at their respective advantages and disadvantages.

1. The advantages and disadvantages of hard rail and its application

The hard rail has a large sliding contact surface, good rigidity, strong shock resistance, strong load-bearing capacity, and is suitable for heavy-duty cutting.

The hard rail is dry friction. Due to the large contact surface, the friction resistance is also large, and the moving speed cannot be too fast. At the same time, crawling is easy to occur, and the gap on the moving surface will cause machining errors. The maintenance of the machine tool track is the top priority. Once the track is not sufficiently lubricated, it will cause the track to burn or wear out, which is fatal to the accuracy of the machine tool.

The application of hard rails is suitable for heavy cutting, large molds, high hardness workpieces, and workpieces with general accuracy requirements.

2. The advantages and disadvantages of the line rail and its application

Nowadays, many machine tools are running extremely fast, especially the idle speed. This is largely due to the credit of the linear rail; the linear rail can be pre-tightened to achieve zero gap between the rails with high accuracy; in terms of service life, the linear rail The rail is much higher than the hard rail.

The cutting force of the linear rail is smaller than that of the hard rail. It is only for the hard rail. In fact, the linear rails of many machine tools have greatly improved their carrying capacity.

The application of linear rail is suitable for high-speed machines, high-speed machining cutting, suitable for processing products and small precision molds. Nowadays, more precision machining centers use linear rails.

Categories

latest blog

© Copyright: 2026 Lyter Engineering Ltd. All Rights Reserved

IPv6 network supported